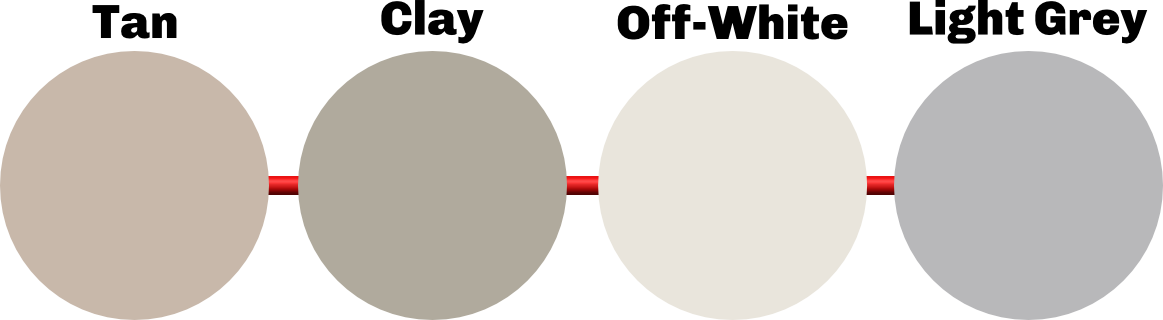

Our four standard colors are light in tone because when a deck surface is exposed to sunlight, temperatures can be excessive. That kind of heat may result in the peeling and blistering of the finish gelcoat. The lighter colors do not get as hot. Custom colors are available but please note, our supplier cannot guarantee 100% match.

The Process

All of Polymite’s fiberglass decks start with the installation of ½” plywood to be installed by the contractor or Polymite team. We use PL 400 Wood Glue with screws to fasten the plywood to the ¾” subfloor. Doing this reduces the possibility of squeaky wood, cracking seams, and nail pops.

Azek trim is hung on the perimeter drip edge of the deck flush with plywood using a finish nail gun. The trim is then routed in order to allow for easy layup and smooth transition for the fiberglass.

Next, Kant strips are installed on all right angles that meet the deck. Once completed, the entire deck is sanded and nails/seams are filled with polyester putty to ensure no voids that would diminish the integrity of the fiberglass.

We then clear the deck of all debris. Fiberglass is fit and applied with resin to cover the interior walls, drip edge, flashing, and door pans. The same process is used to install the remaining deck surface or floor. Once the resin is fully cured, a coat of colored gelcoat is applied.

The last step is to fully sand out any imperfections and reapply a final coat of non-slip gelcoat for that final, clean finish.

Fiberglass decking has a life expectancy of 30-40 years. During that time it is recommended to re-topcoat every 8-10 years for maintenance With proper care, your deck surface will have a long, hardy and beautiful life!

Deck Preparation Specifications